THE ALLROUND-MACHINE FOR ALL JOBS

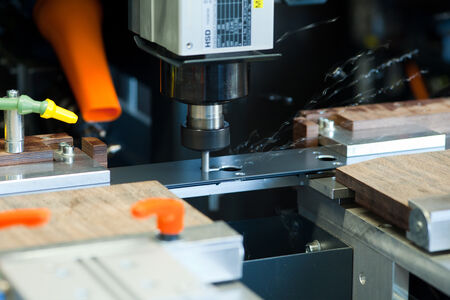

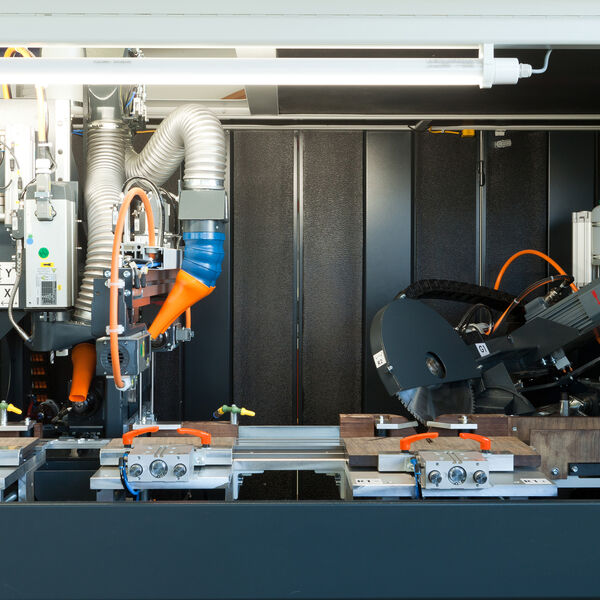

The GLS-2 is the extremely efficient and top-performing CNC-controlled allround machining center for cutting, punching, drilling, milling and printing of profiled bars – semi- or fully-automated.

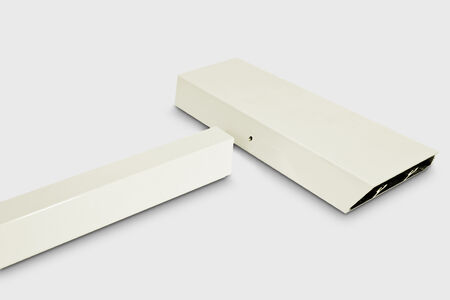

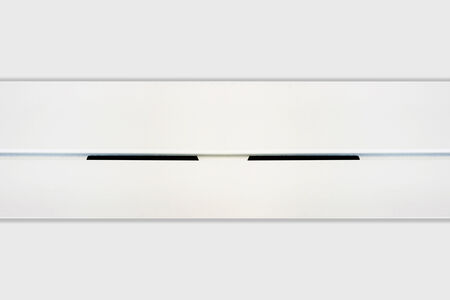

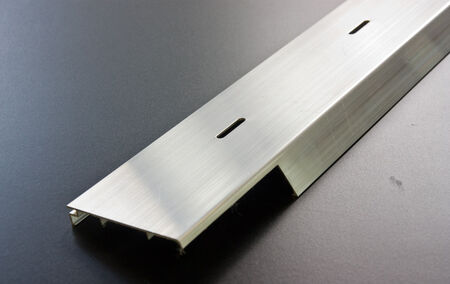

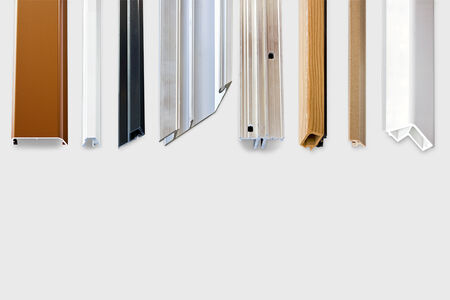

The Machining Center for Profiled Stock GLS-2 can produce high-quality glazing beads, door profiles, rain protection rails, etc. of wood, aluminum, MDF or PVC efficiently in series production.

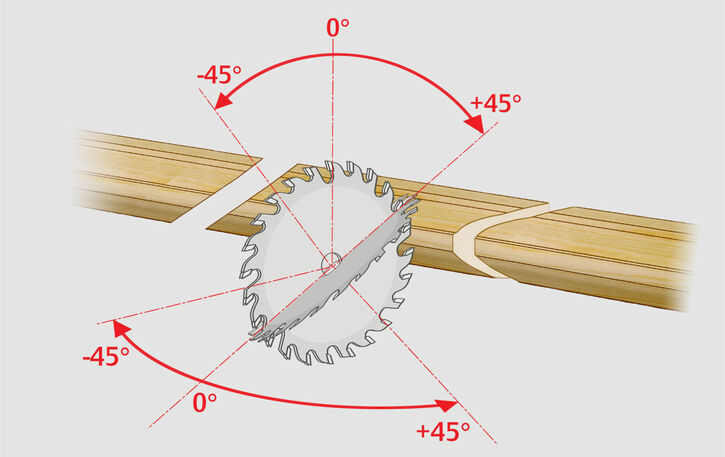

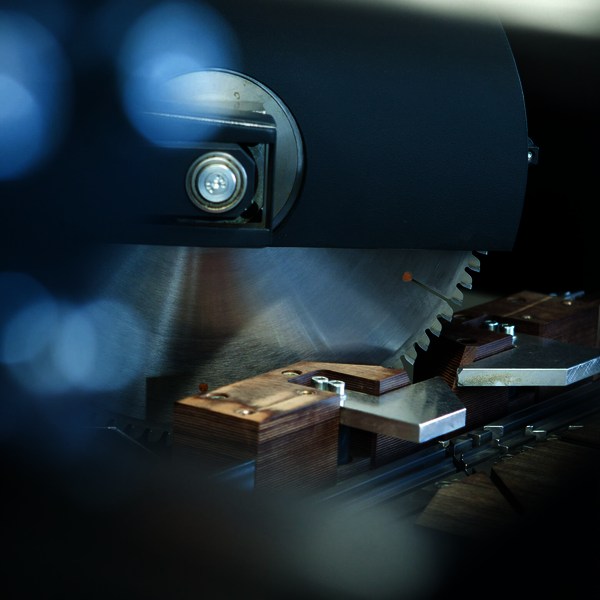

PERFECT CUTTING TO LENGTH. 100% TEAR-FREE.

Downloads

Alu-Center GLS-2 208.1 KB

Manufacturing program 4.5 MB

Your contact person

Sales & service

Rainer Böhm, +49 9402 501 22

Sales & service international

Aldona Piecha, +49 9402 501 23

Sales & service international

Ulrike Gahr, +49 9402 501 27

Contact form

Have you got any questions or would you like to inform us on something?

We look forward to receiving your message.